商铺名称:上海双慕机电科技有限公司

联系人:赵先生(先生)

联系手机:

固定电话:

企业邮箱:shsm1982@163.com

联系地址:普陀区中山北路2668号

邮编:203361

联系我时,请说是在地方电气网上看到的,谢谢!

商品详情

Kjellberg电极

Upgrade to Centricut performance

consumables to lower your operating

costs without sacrificing cut quality

and productivity.

Lower overall costs

? Centricut consumables last more than 15% longer than

Kjellberg mild steel consumables.

? Full line of consumables for all cutting applications are

competitively priced compared to the OEM.

? Local stocking and fast delivery reduce your inventory costs.

Hypertherm patented technology

? As the recognized global leader in plasma cutting, Hypertherm

incorporates the latest engineered technologies into all

consumable products.

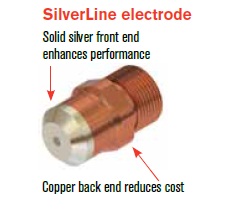

? SilverLine? electrodes and CoolFlow? nozzles deliver

exceptional cut quality and fast cutting speeds over the full life

of the consumables.

? Centricut consumables set the standard by which other

manufacturers measure themselves.

Cut with confidence – it’s Hypertherm

? Designed with critical-to-function tolerances to deliver the best

quality product every time.

? Precision manufacturing of consumables assures consistency

of parts set to set.

? World-class plasma-process technical support.

? Easy to use – no special system set up required.

To achieve maximum consumable life

A fully used SilverLine? electrode will have a

pit depth of 2.5 mm (.100").

Properly tighten the nozzle cap: Make

sure the nozzle cap is sealed tightly against

the nozzle to maintain a proper seal and

prevent leaking.

Purge torch and leak check: After each

parts change purge the torch for at least

30 seconds to remove residual moisture.

Check for leaks.

Adjust gas flows: Plasma gas flow rate is

critical. High flow will cause rapid electrode

wear and hard starting. Low flow will cause

uncontrolled arcing. (See cutting tables in

your owner’s manual.)

Pierce at correct height: Piercing too low

causes molten metal (spatter) to hit the swirl

gas cap and nozzle. This is the most common

cause of premature nozzle failure. Piercing

Reference

number

Article

number Description

Centricut

number

1. K2-XL .11.828.921.300 SilverLine electrode C53-1000

K2 .12.40870 Electrode C53-870

2. K5 .11.828.911.550 Electrode ArH2 C117-0550

3. .12.40860 Gas guide cap C53-860

4. L1-XL .11.828.901.420 CoolFlow nozzle, O2, 160A C53-920

L2-XL .11.828.901.425 CoolFlow nozzle, O2, 250A C53-925

L4-XL .11.828.901.427 CoolFlow nozzle, O2, 300A C53-927

L1 .12.4305 Nozzle, Air, 160A, 2.0 mm C53-050

L2 .12.40850 Nozzle, Air, 250A, 2.5 mm C53-850

5. A1 .12.37780 CoolFlow nozzle, ArH2, 120A, 1.5 mm C117-780

A3 .11.828.511.620 CoolFlow nozzle, ArH2, 180A, 2.0 mm C117-620

A2 .12.40910 CoolFlow nozzle, ArH2, 300A, 2.3 mm C117-910

6. V3000 .12.37790 Nozzle cap C53-790

7. V521 .11.833.101.271 Swirl gas nozzle K53-271

8. V501 .11.833.101.261 Protective cap C53-261

.11.828.701.160 Protective cap PB-S75 K53-160

9. V4540 .11.833.111.156 Swirl gas cap, 4.0 mm K53-1156

V4550 .11.833.101.158 Swirl gas cap, 5.0 mm C53-158

.11.828.911.230 Cooling tube PB-S75 ArH2 C117-230

.12.51440 Cooling tube PB-S75 Air K53-440

too high can cause slow arc transfer and

misfires.

Adjust arc voltage: As the electrode wears,

the torch will get closer to the plate. To maintain

optimum cutting height, increase arc voltage in

2-volt increments, up to 10 volts higher than

the initial setting.

Avoid arc stretching: This can occur during

rip cutting off the plate or when the lead out

is improperly programmed. This shortens

consumable life.

Clean the nozzle and swirl gas cap:

Periodically clean the nozzle and swirl gas cap

to remove spatter. This will prevent double

arcing which shortens consumable life.

Adjust swirl gas flows: Correct swirl gas

flows during pre-flow protect the nozzle and

swirl gas cap from damage. Make sure pre-flow

is adjusted according to the cutting tables in

your owner’s manual.

Upgrade to Centricut performance

consumables to lower your operating

costs without sacrificing cut quality

and productivity.

Lower overall costs

? Centricut consumables last more than 15% longer than

Kjellberg mild steel consumables.

? Full line of consumables for all cutting applications are

competitively priced compared to the OEM.

? Local stocking and fast delivery reduce your inventory costs.

Hypertherm patented technology

? As the recognized global leader in plasma cutting, Hypertherm

incorporates the latest engineered technologies into all

consumable products.

? SilverLine? electrodes and CoolFlow? nozzles deliver

exceptional cut quality and fast cutting speeds over the full life

of the consumables.

? Centricut consumables set the standard by which other

manufacturers measure themselves.

Cut with confidence – it’s Hypertherm

? Designed with critical-to-function tolerances to deliver the best

quality product every time.

? Precision manufacturing of consumables assures consistency

of parts set to set.

? World-class plasma-process technical support.

? Easy to use – no special system set up required.

To achieve maximum consumable life

A fully used SilverLine? electrode will have a

pit depth of 2.5 mm (.100").

Properly tighten the nozzle cap: Make

sure the nozzle cap is sealed tightly against

the nozzle to maintain a proper seal and

prevent leaking.

Purge torch and leak check: After each

parts change purge the torch for at least

30 seconds to remove residual moisture.

Check for leaks.

Adjust gas flows: Plasma gas flow rate is

critical. High flow will cause rapid electrode

wear and hard starting. Low flow will cause

uncontrolled arcing. (See cutting tables in

your owner’s manual.)

Pierce at correct height: Piercing too low

causes molten metal (spatter) to hit the swirl

gas cap and nozzle. This is the most common

cause of premature nozzle failure. Piercing

Reference

number

Article

number Description

Centricut

number

1. K2-XL .11.828.921.300 SilverLine electrode C53-1000

K2 .12.40870 Electrode C53-870

2. K5 .11.828.911.550 Electrode ArH2 C117-0550

3. .12.40860 Gas guide cap C53-860

4. L1-XL .11.828.901.420 CoolFlow nozzle, O2, 160A C53-920

L2-XL .11.828.901.425 CoolFlow nozzle, O2, 250A C53-925

L4-XL .11.828.901.427 CoolFlow nozzle, O2, 300A C53-927

L1 .12.4305 Nozzle, Air, 160A, 2.0 mm C53-050

L2 .12.40850 Nozzle, Air, 250A, 2.5 mm C53-850

5. A1 .12.37780 CoolFlow nozzle, ArH2, 120A, 1.5 mm C117-780

A3 .11.828.511.620 CoolFlow nozzle, ArH2, 180A, 2.0 mm C117-620

A2 .12.40910 CoolFlow nozzle, ArH2, 300A, 2.3 mm C117-910

6. V3000 .12.37790 Nozzle cap C53-790

7. V521 .11.833.101.271 Swirl gas nozzle K53-271

8. V501 .11.833.101.261 Protective cap C53-261

.11.828.701.160 Protective cap PB-S75 K53-160

9. V4540 .11.833.111.156 Swirl gas cap, 4.0 mm K53-1156

V4550 .11.833.101.158 Swirl gas cap, 5.0 mm C53-158

.11.828.911.230 Cooling tube PB-S75 ArH2 C117-230

.12.51440 Cooling tube PB-S75 Air K53-440

too high can cause slow arc transfer and

misfires.

Adjust arc voltage: As the electrode wears,

the torch will get closer to the plate. To maintain

optimum cutting height, increase arc voltage in

2-volt increments, up to 10 volts higher than

the initial setting.

Avoid arc stretching: This can occur during

rip cutting off the plate or when the lead out

is improperly programmed. This shortens

consumable life.

Clean the nozzle and swirl gas cap:

Periodically clean the nozzle and swirl gas cap

to remove spatter. This will prevent double

arcing which shortens consumable life.

Adjust swirl gas flows: Correct swirl gas

flows during pre-flow protect the nozzle and

swirl gas cap from damage. Make sure pre-flow

is adjusted according to the cutting tables in

your owner’s manual.